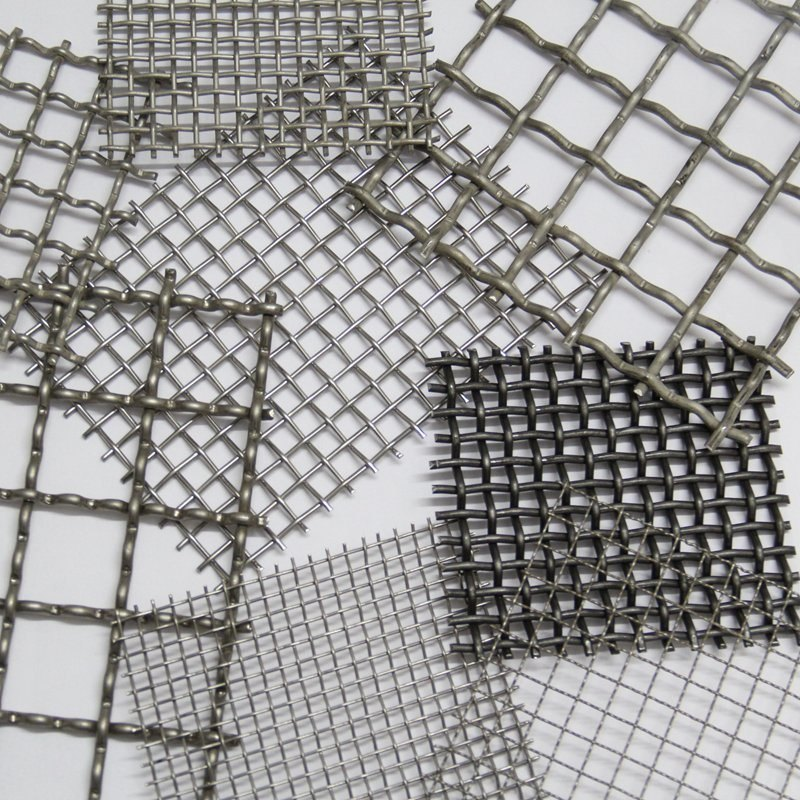

Stainless steel wire mesh is a versatile material with a wide range of applications across different industries. Let’s delve into the different types of stainless steel wire mesh available:

## Braided Wire Rope: Strength and Flexibility

Braided wire rope is known for its strength and flexibility, making it ideal for applications that require durability and manoeuvrability. This type of wire rope is commonly used in lifting, towing, and marine applications due to its ability to withstand heavy loads and harsh conditions.

## Mesh Wire: Versatile and Functional

Mesh wire offers versatility and functionality in various applications, including fencing, filtration, and architectural design. Its grid-like structure provides strength and visibility while allowing airflow and light transmission. Mesh wire is a popular choice for both decorative and functional purposes.

## Crimping Wire: Secure Connections for Rigging

Crimping wire is used to create secure connections in rigging applications where strength and reliability are essential. It is commonly employed in construction, marine, and industrial settings to join cables securely without the need for welding or soldering. Crimping wire ensures safe and efficient rigging operations.

## Galvanized Wire: Corrosion Resistance for Durability

Galvanized wire mesh is coated with zinc to enhance its corrosion resistance, making it suitable for outdoor applications exposed to moisture and harsh environments. It offers durability and longevity, making it a cost-effective solution for fencing, agriculture, and construction projects.

## Stainless Steel Wire Gauge: Precision Measurement for Strength

Stainless steel wire gauge is a measurement standard used to determine the diameter of stainless steel wires. It plays a crucial role in ensuring the strength and performance of stainless steel wire mesh in various applications. Choosing the right wire gauge is essential for meeting specific load-bearing requirements.

In conclusion, stainless steel wire mesh comes in various types such as braided wire rope, mesh wire, crimping wire, galvanised wire, and stainless steel wire gauge, each offering unique properties suited for different applications. Whether you need strength, flexibility, corrosion resistance, secure connections, or precise measurements, stainless steel wire mesh provides a reliable solution for a wide range of industrial needs.

The Unsung Hero of Construction: Welded Wire Mesh and its Many Uses

The world of construction relies on a multitude of materials, each playing a vital role in bringing structures to life. While steel beams and concrete slabs often take center stage, there’s an unsung hero lurking beneath the surface – welded wire mesh.

Welded wire mesh, also known as welded wire fabric (WWF), is a versatile material formed by welding horizontal and vertical steel wires at their intersections. This creates a strong, grid-like structure with various applications across the construction spectrum.

The Power of Reinforcement:

One of the most crucial uses of welded wire mesh is as reinforcement mesh in concrete structures. Imagine concrete as a powerful force, but prone to cracking under pressure. Reinforcement mesh acts as an internal skeleton, evenly distributing stress throughout the concrete and preventing cracks from forming. This is particularly important for elements like floors, slabs, and walls that need to withstand heavy loads.

Beyond Concrete: Applications Galore

While concrete reinforcement is a major use case, welded wire mesh offers a surprising range of other applications:

- Hardware Cloth: Made from thinner gauge wires, hardware cloth is a type of welded wire mesh commonly used for creating cages, screens, and enclosures for small animals and tools.

- Perimeter Security Mesh: When it comes to securing your property, welded wire mesh steps up as perimeter security mesh. Fence panels made from this material offer a strong and durable barrier for homes, businesses, and construction sites. For added durability, galvanised welded mesh is often preferred, as the zinc coating provides superior corrosion resistance.

- More Than Meets the Eye: Welded wire mesh isn’t just about strength and security. It can also play a role in aesthetics. Welded wire mesh panels can be used creatively for decorative purposes, such as wall accents or garden features.

Choosing the Right Mesh:

Welded wire mesh comes in various configurations to suit different needs. The thickness of the wires (gauge), the size of the grid openings, and the overall panel size are all factors to consider. Additionally, galvanised welded mesh is a popular option for outdoor applications due to its enhanced corrosion resistance.

The Benefits of Using Welded Wire Mesh:

- Strength and Durability: The welded construction ensures a strong and rigid structure that can withstand significant loads and harsh conditions.

- Versatility: Welded wire mesh has a wide range of applications, making it a valuable material for various construction projects.

- Cost-Effective: Compared to other reinforcement materials, welded wire mesh offers a cost-effective solution while delivering excellent performance.

- Ease of Use: Welded wire mesh is lightweight and easy to handle, making it a user-friendly material for construction projects.

Decoding Welded Wire Mesh: Choosing the Right Armour for Your Project

Welded wire mesh might seem like a simple product, but it’s a surprisingly versatile workhorse in the construction industry. However, with all that versatility comes a variety of options to consider. Understanding these options, like wire gauge, mesh opening, roll or panel, electro welded mesh, and even the material itself (stainless steel welded mesh), is key to choosing the right mesh for your project.

Wire Gauge: Imagine wire gauge as the “thickness” of the wires in the mesh. A lower gauge number indicates a thicker wire, offering greater strength. For heavy-duty concrete reinforcement, a lower gauge is ideal. For applications like animal cages, a higher gauge (thinner wire) provides sufficient strength while maintaining workability.

Mesh Opening: This refers to the size of the square or rectangular gaps within the mesh. A smaller opening offers superior reinforcement and security, while a larger opening allows for more airflow or light penetration. Choosing the right size depends on the application.

Roll or Panel: Welded wire mesh comes in two formats: rolls and panels. Rolls provide continuous lengths of mesh, ideal for projects requiring custom cuts. Panels are pre-cut sections, offering a faster and easier installation process for applications with consistent size requirements.

Electro Welded Mesh: The most common type of welded mesh uses electric resistance welding to join the wires at each intersection. This creates a strong and reliable connection, making electro welded mesh suitable for most applications.

Stainless Steel Welded Mesh: For environments prone to corrosion, stainless steel welded mesh provides a superior option. The inherent corrosion resistance of stainless steel makes it ideal for applications like marine construction, chemical plants, or areas with high humidity.

Choosing the Right Mesh:

By considering these factors – wire gauge, mesh opening, roll or panel, and material – you can select the welded wire mesh that best suits your project needs. For example, a heavy-duty concrete slab might require a low-gauge, electro welded mesh in a panel format. Meanwhile, a secure animal enclosure might benefit from a higher gauge, smaller opening mesh in a roll format for easy customization.

The Takeaway: