Vibrating Screens

Introduction

In the vast landscape of industrial machinery, vibrating screens stand out as versatile and indispensable components.

These devices play a pivotal role in various industries, ranging from mining and construction to ceramics and beyond.

In this comprehensive exploration, we delve into the intricacies of vibrating screens, uncovering their types, applications, and specifically focusing on horizontal vibrating screens and their significance in glazing applications.

Understanding Vibrating Screens

Vibrating screens are mechanical separators used for a myriad of purposes, primarily sorting, grading, and screening of materials.

Their fundamental principle lies in the vibration-induced motion that facilitates the separation of particles based on size and shape.

These screens operate with an oscillating motion generated by an eccentric shaft or unbalanced flywheel.

Types of Screens

1. Circular Screens:

Circular screens are characterized by their circular motion, creating a uniform and efficient screening process.

Widely used in mining, construction, and chemical industries, these screens excel in screening granular materials.

2. Linear Screens:

Linear screens move in a straight line, allowing for high-capacity screening and efficient material conveyance.

Commonly employed in industries like food processing and pharmaceuticals.

3. Elliptical Screens:

Combining the advantages of circular and linear motion, elliptical vibrating screens offer improved screening efficiency.

Ideal for screening fine and ultra-fine materials in various industries.

4. High-Frequency Screens:

These screens operate at higher frequencies, enhancing the efficiency of fine particle separation.

Often used in the processing of minerals and high-quality aggregates.

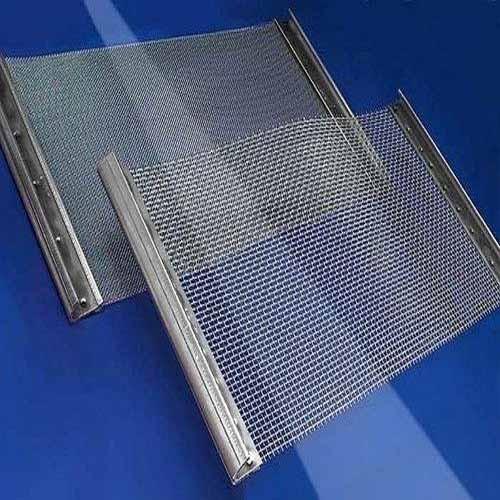

Horizontal Vibrating Screens

Among the diverse types of screens, horizontal screens hold a significant place, especially in industries where a horizontal screening surface is preferred.

Advantages of Screens:

Uniform Screening: The orientation ensures a uniform distribution of material across the screen deck, allowing for consistent and efficient screening.

High Efficiency: screens are known for their high screening efficiency, making them suitable for various applications.

Reduced Wear and Tear: The motion reduces the wear and tear on screen media, extending the lifespan of the equipment.

Versatility: Suitable for both wet and dry screening, vibrating screens adapt to diverse material handling requirements.

Applications of Horizontal Screens:

Aggregate Processing: Used for separating aggregates of different sizes in the construction and mining industries.

Mineral Processing: Ideal for sorting and classifying minerals based on size and density.

Recycling: Employed in recycling plants for sorting and separating recycled materials.

Sand and Gravel Screening: Widely used in sand and gravel operations for efficient particle separation.

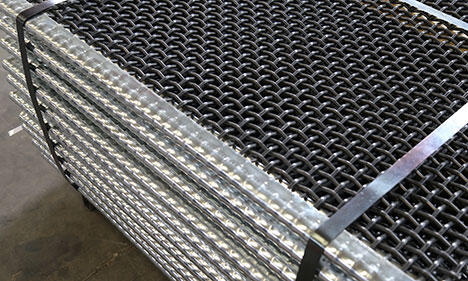

Vibrating Screens for Glazers

In the ceramics industry, the precision and quality of glazing processes are paramount. screens designed for glazing applications play a crucial role in ensuring a smooth and efficient glazing operation.

Key Features of Vibrating Screens for Glazers:

Fine Particle Separation: The screens are designed to efficiently separate fine particles from the glazing mixture, ensuring a high-quality glaze.

Consistent Thickness: By removing impurities and ensuring uniform particle distribution, these screens contribute to achieving a consistent glaze thickness.

Customizable Deck Configurations: screens for glazing applications often come with customizable deck configurations, allowing for precise control over the screening process.

High Throughput: These screens are engineered for high throughput, meeting the demands of large-scale glazing operations.

Benefits of Using Screens in Glazing:

Quality Enhancement: Vibrating screens contribute to the overall quality enhancement of glazed products by ensuring that the glaze is free from unwanted impurities.

Operational Efficiency: The use of vibrating screens streamlines the glazing process, reducing manual intervention and increasing operational efficiency.

Cost Savings: Improved efficiency and reduced waste translate to cost savings, making vibrating screens a cost-effective investment for glazing operations.

Industrial Screens

Beyond glazing applications, industrial screens find their utility in a myriad of industries, contributing to efficient material handling and processing.

Diverse Industrial Applications:

Mining and Quarrying: Industrial vibrating screens are extensively used in mining and quarrying operations for sorting and classifying various minerals and aggregates.

Chemical Processing: In the chemical industry, these screens facilitate the separation of different chemicals based on size, contributing to the production of high-quality chemical products.

Food and Beverage: Vibrating screens play a crucial role in the food and beverage industry, ensuring the quality and safety of food products by efficiently separating and screening ingredients.

Recycling: Industries involved in recycling benefit from the use of vibrating screens for sorting and classifying recycled materials.

Considerations for Selecting Industrial Vibrating Screens:

Material Characteristics: The type and characteristics of the material being processed influence the choice of vibrating screen.

Throughput Requirements: Industrial processes often demand high throughput, and the capacity of the screen should align with these requirements.

Environmental Factors: Consideration of environmental factors such as moisture content and temperature is crucial for optimal performance.

Conclusion

Vibrating screen, with their diverse types and applications, are indispensable tools in various industries. Horizontal screens, with their unique advantages, find prominence in glazing applications, contributing to the precision and efficiency of the glazing process in the ceramics industry.

As technology continues to evolve, so too will the design and capabilities of screens, ensuring they remain at the forefront of industrial machinery, providing essential solutions for material handling and processing challenges across the globe.